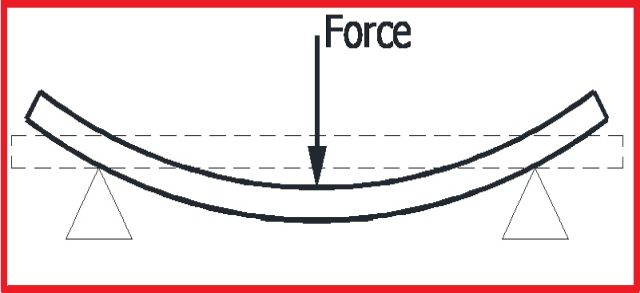

The sandwich effect

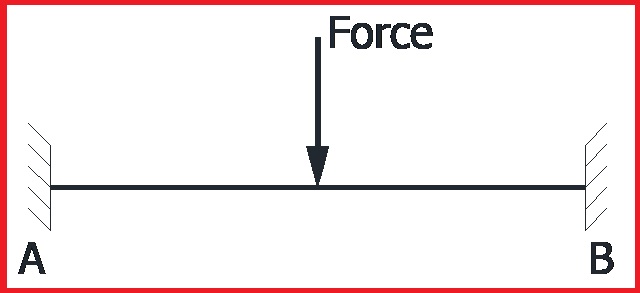

The drum effect

How to make an XL-compliant Ultra-Light dry freight truck body? POLYFONT and Aluvan created the eCoVan.

Over the last 50 years of panel manufacture, POLYFONT has been researching how to best utilise the “sandwich” and “drum” effects in panels. The glass fibres in our skins make elongation impossible : this is known as the “sandwich effect”. If A and B are fixed (captive mounting) the panel can not bend : this is known as the “drum” effect. Today POLYFONT is pleased to launch the new EcoFont UL (Ultra Light) in 14mm which responds to this quest and weighs a mere 3,2kg/m². Simultaneously, Aluvan has come up with a new body kit design using the EcoFont UL panel, with incredible ingenuity. Not only is the body kit exceptionally light, but it is also XL-rated, having passed the strenuous XL certification tests with flying colours (tests based on 2700kg load and 4,2m body length).

The exceptional EcoFont UL panel is also used for the access panels, rear- side- and sliding doors. The tie-rails, either surface-mounted or semi-recessed, are guaranteed for up to 250kg of tensile force. POLYFONT has never compromised on safety, structural strength and load restraint systems.

To our knowledge, not a single accident attributed to body structure has ever occured in 50 years. For our next ultra-light truck body without compromise on safety, consider POLYFONT panels and Aluvan kits. You will be pleasantly surprised getting acquainted with the brandnew eCoVan.

For your next fleet of carbon-efficient lightweight truck bodies, Aluvan and POLYFONT can accompany you all the way.